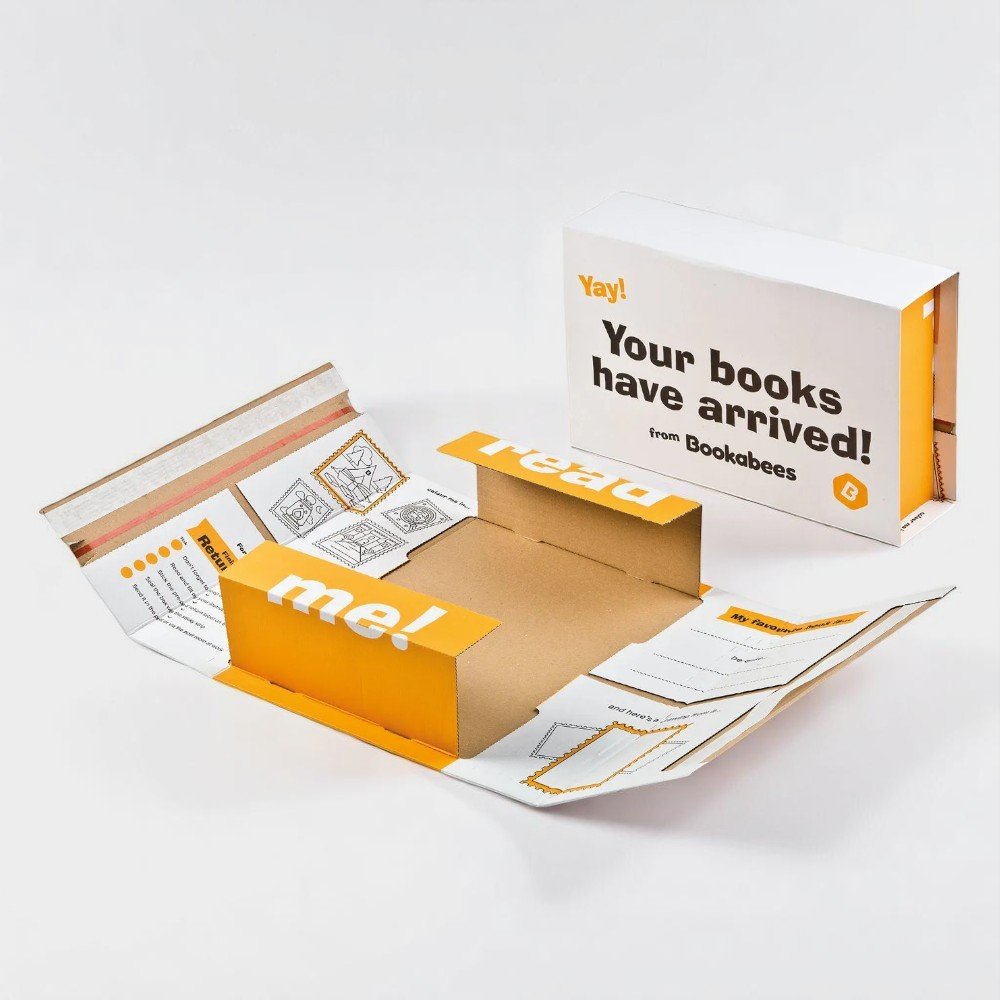

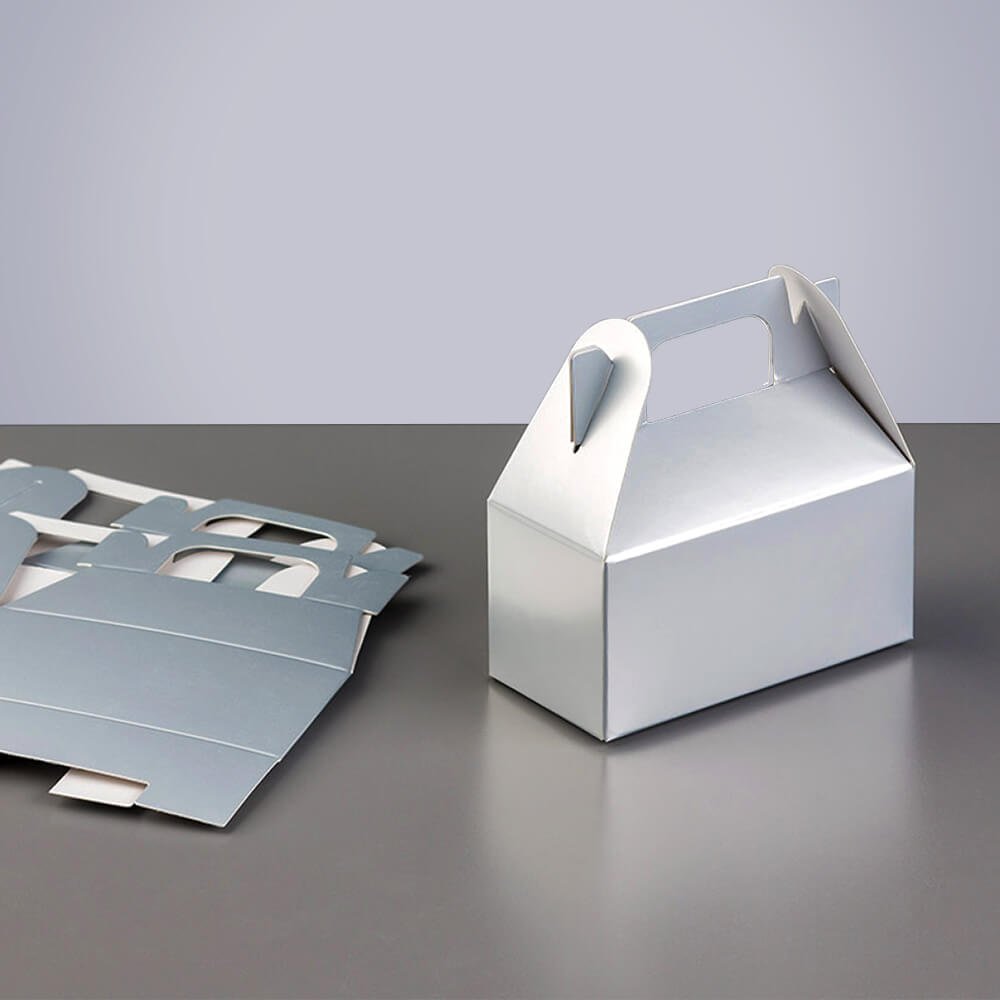

Steps for the Custom Box Production

We take the stress out of custom packaging. Our simple, step-by-step process helps you create packaging that fits your product and supports your business goals.

Find the Right Packaging

Pick the perfect box style, size, and design that suits your product. Contact us to tell us your unique requirements.

Get a Fast and Free Quote

After sharing your requirements, we’ll send a no-obligation quote that will be quick, clear, and complete with eco-friendly options.

Review and Approve

We’ll double-check every detail, send over a design proof, and make sure everything looks just right before we move forward.

Begin Production with Ease

Once approved, we’ll start production using smart, cost-effective methods, giving you quality packaging without blowing your budget.

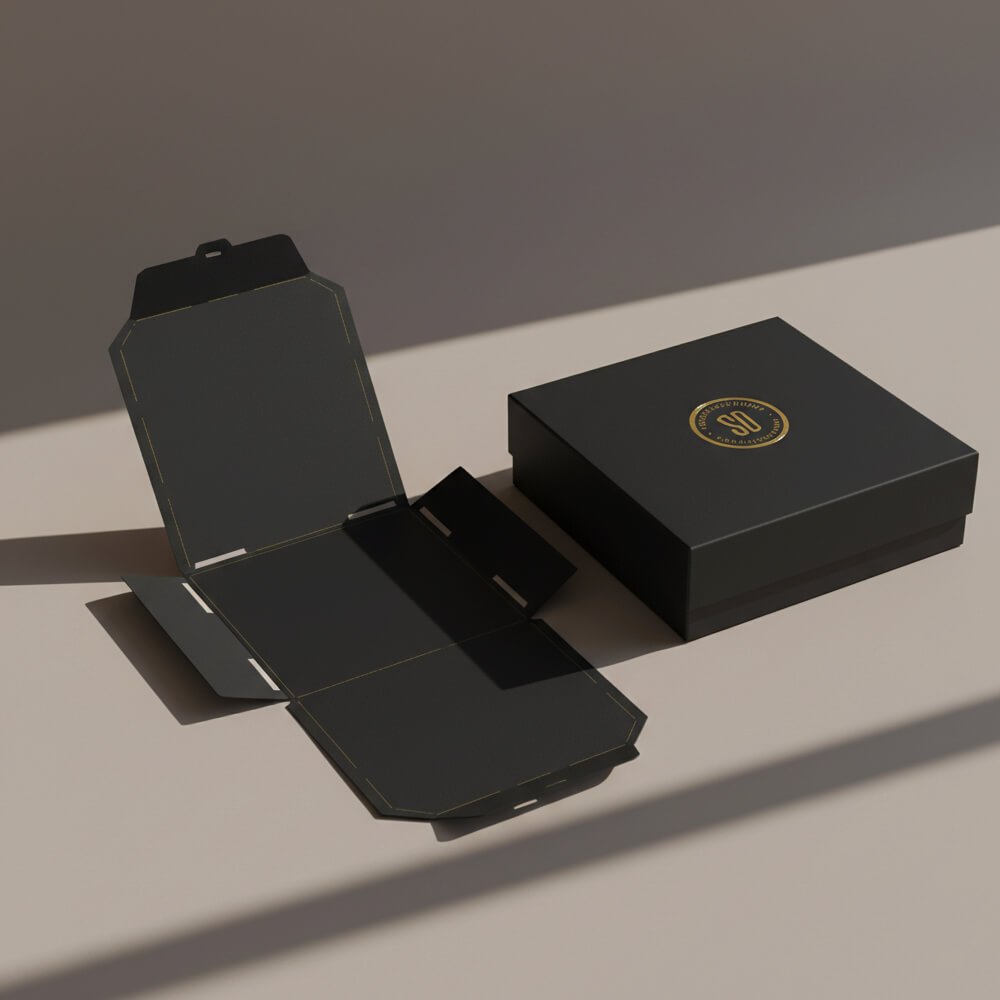

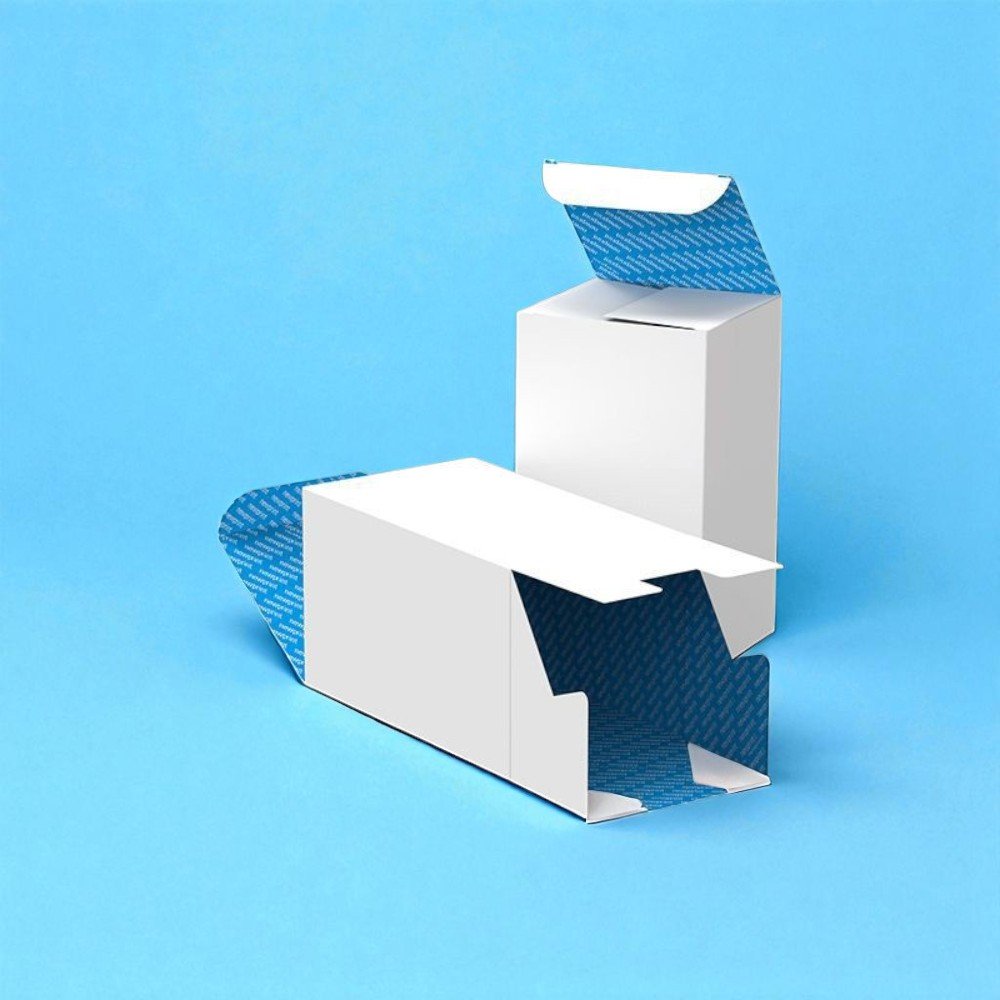

Use Custom Electronic Shipping Boxes To Protect Your Electronic Goods

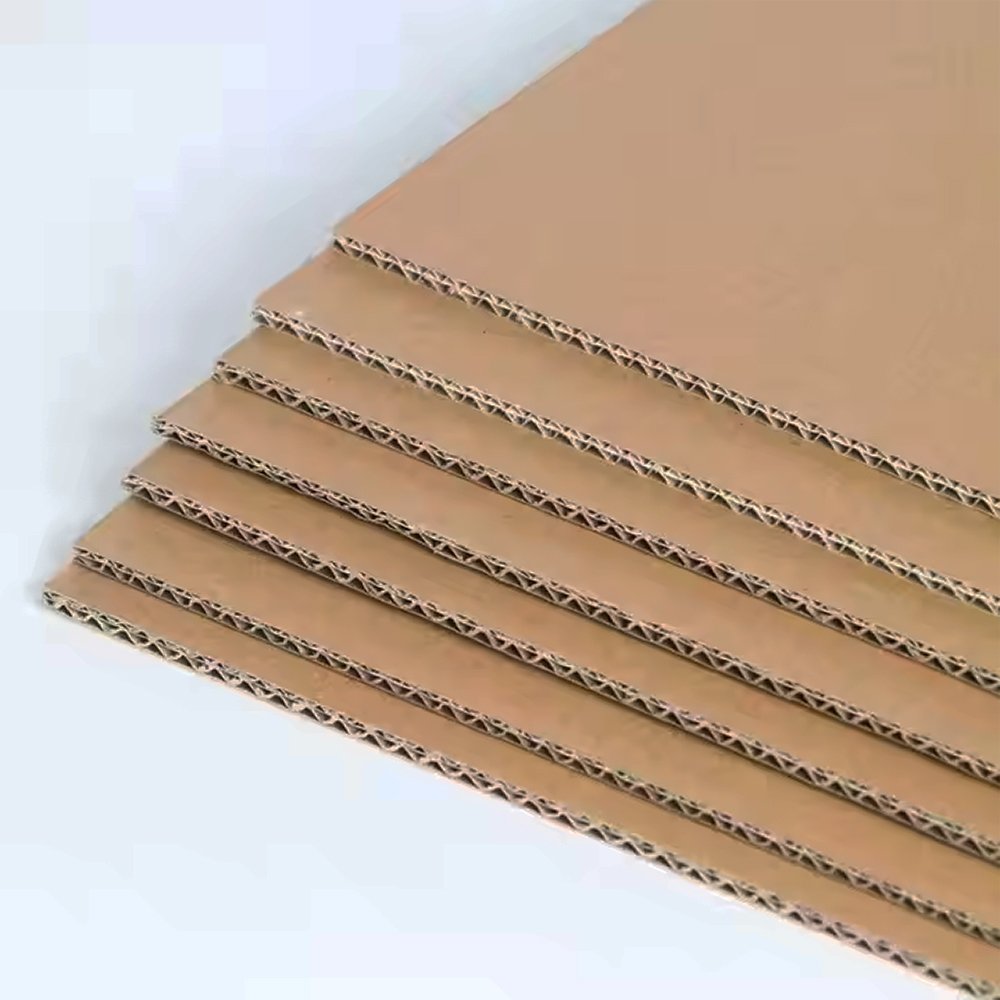

Electronic products are super fragile and they can be easily damaged during shipping leading to major financial losses for businesses. Product damage also leads to unsatisfactory customers. When a customer receives damaged products they won’t order from that brand again. The worst part is customer’s also leave a negative review on your site that damages your brand image. Now this is very dangerous for businesses that sell their goods online. As you know customers order products on an online store based on their reviews. Now being the client of UPacked we do not want negative sentiments around your brand. That is why we offer durable custom electronic boxes. These custom packaging for electronic products are made up of corrugated cardboard. It is one of the most durable materials that you can use for packaging. By packing your electronic products inside these you can ensure they won’t get damaged during shipping.Customized Electronic Packaging For Your Valuable Devices

Electronic industry offers various products from speakers to LED lights, from light bulbs to cameras, and more. These custom printed electronic packaging boxes with logos can be customized according to your branding needs. As you know each electronic product is different from one another and that is why they require packaging that is specially designed for them. This is where we can help you. Our boxes are tailored according to the theme of your products.Enhance The Presentation Of Your Electronic Products With Our Eye-Catching Styles

If you want to pack your electronic products in a stylish manner then you have to choose the right packaging style. At UPacked, we offer different custom styles of boxes for your electronic products such as custom tuck boxes, magnetic closure, custom window boxes, two piece, custom mailer boxes, custom sleeve boxes, and more. Each of these products serves a unique selling proposition and has their own unique cases. For example if you sell expensive electronic goods then you have to pack inside premium boxes such as drawer, two-piece, or magnetic closure boxes. These boxes are made up of rigid material which is one of the most premium packaging materials that you can use packing. If you have a tight budget then you can go for our tuck style boxes. They are made from cardboard or kraft material. Both of these materials are recyclable and compostable. You can also request to add custom inserts. These inserts are specially designed for your products. With the help of them you can easily enhance the presentation of your electronic items. Plus these inserts also add an extra layer of protection.We Have Latest Printing Technology Machines

Getting your boxes printed with advanced technology machines is equally important. As you know, electronic product boxes are filled with different colors, so you need to have them printed with advanced machines to ensure accurate color reproduction. If you get personalized electronic packaging from UPacked then you don’t have to worry about it because our printing machines support both CMYK & PMS colors. We use different printing techniques such as offset, digital, flexographic, and more.Fascinating Finishing & Add-Ons Options

If you want to make your packaging more attractive to the customer's eyes then you have to choose the right finishing for it. When choosing the finishing option for your custom electronic packaging you have to ensure it catches customer’s attention. Your finishing option also complements your brand theme. Considering this we offer a wide range of finishing options such as gloss, matte, soft touch, and more. Another way to differentiate your electronic items from the rest of the competition on the shelf is by choosing the right add-ons. They are like dresses for your boxes. We offer different add-ons such as inserts, lamination, foiling, window, die-cuts, and more. Each of these add-ons serves a unique purpose. For example if you want to protect your electronic goods from hazards such as dust and moisture while showcasing the beauty of it then you can choose our custom window boxes. If simple yet elegant and affordable packaging is your main concern then you can choose our tuck style boxes. If you are not sure what packaging style works best for your electronic products then you can get in touch with our customer support department. Our packaging experts can help you choose the right packaging style for your custom electronic packaging boxes.Why 1000+ Companies Have Shown Their Trust In Us?

UPacked is the name of trust. We offer affordable custom boxes and custom packaging for all businesses in the United States. We offer wholesale prices, free shipping 24/7 customer support, fast turnaround time, free packaging expert guidance, and more.| Dimensions: | All Custom Sizes & Shapes |

|---|---|

| Quantities: | Start from 100 Quantity |

| Paper Stock: | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Printing: | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

| Finishing: | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options: | Die Cutting, Gluing, Scored, Perforation |

| Additional Options: | Eco-Friendly, Recycled Boxes, Biodegradable |

| Proof: | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround: | 6 – 8 Business Days, RUSH |

| Shipping: | FLAT |

Win More Customers with Personalized Clothing Boxes

Make over your packaging into something new. Choose from a variety of materials and customization options to create boxes that are specific to your brand.

UV Coating

UV coating gives packaging high-gloss shine. It’s cured with ultraviolet light, adding a premium finish that makes colors pop and surfaces more resistant.

Aqueous Coating

Aqueous coating is water-based and eco-friendly. It offers a smooth, quick-drying protective layer. It helps resist smudges and fingerprints with a subtle gloss or matte touch.

Spot Gloss UV

Spot Gloss UV adds a striking contrast by highlighting specific design elements with a glossy finish. It gives packaging a rich, tactile experience that instantly feels upscale.

Soft Touch Coating

Soft Touch Coating adds a velvety, almost suede-like feel to packaging. It is perfect for luxury products or brands aiming to achieve a better look for their boxes.

Varnish

Varnish is a clear coating applied to protect and to improve box surfaces. Available in matte, gloss, or satin finishes. It shields your packaging from moisture and fading.

Lamination

Lamination involves applying a plastic film over your packaging for extra strength. Choose a gloss or matte one to match your style. It protects your design on the box.

Anti-scratch Lamination

Anti-scratch lamination adds a protective film that keeps your packaging looking sharp. It’s resistant to scuffs and scratches, making it ideal for high-end boxes that need to stay flawless through handling.

Soft Touch / Silk Lamination

This lamination gives packaging a silky-smooth texture that feels as good as it looks. It adds a luxurious vibe while also offering extra protection against wear, making it a favorite for premium brands.

Offset Print

Offset printing delivers sharp, high-quality results using metal plates and ink transfer. It offering consistent colors, smooth gradients, and crisp details on the custom boxes.

Digital Printing

Digital printing is a fast, flexible option. It prints directly from the file. No requirement of printing plates. It is ideal for short runs and personalization.

UV Printing

UV printing cures ink instantly with ultraviolet light, producing vibrant, durable prints. It works on various surfaces and resists smudging or fading. This option is a top choice for premium packaging with bold designs.

Water-based Ink

Water-based ink is eco-friendly option and a combination of water and pigments. It produces soft, natural-looking prints while minimizing harsh chemicals, making it a sustainable option.

Soy / Vegetable Ink

Soy-based ink is plant-derived and biodegradable option. It offers rich, vibrant colors with a lower environmental impact. It’s an earth friendly choice without compromising on print quality.

Oil Base Ink

Oil-based ink offers deep saturation and durability, especially for offset printing. It’s a traditional option that is ideal for prints that need to last on the custom packaging.

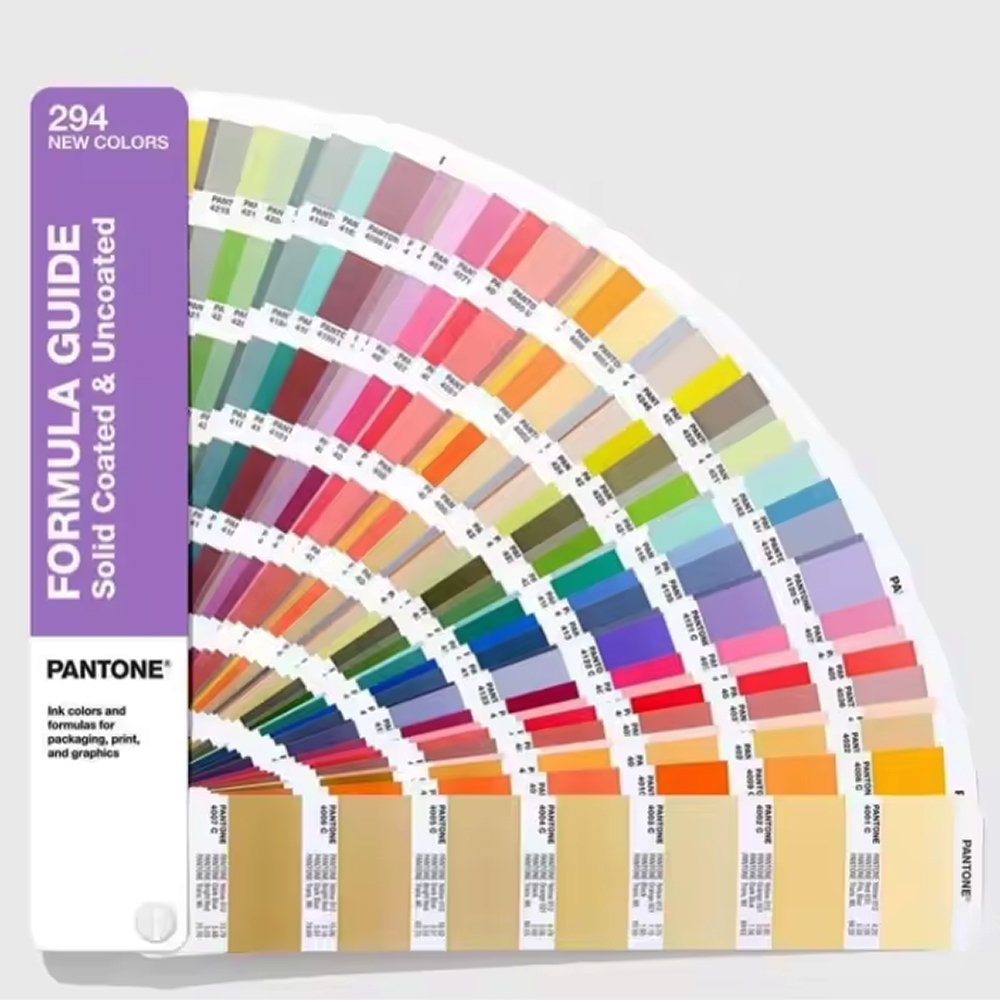

Pantone Ink

Pantone ink uses standardized color matching to ensure absolute color consistency. It delivers precise hues every time, so your packaging always matches your logo or custom palette perfectly.

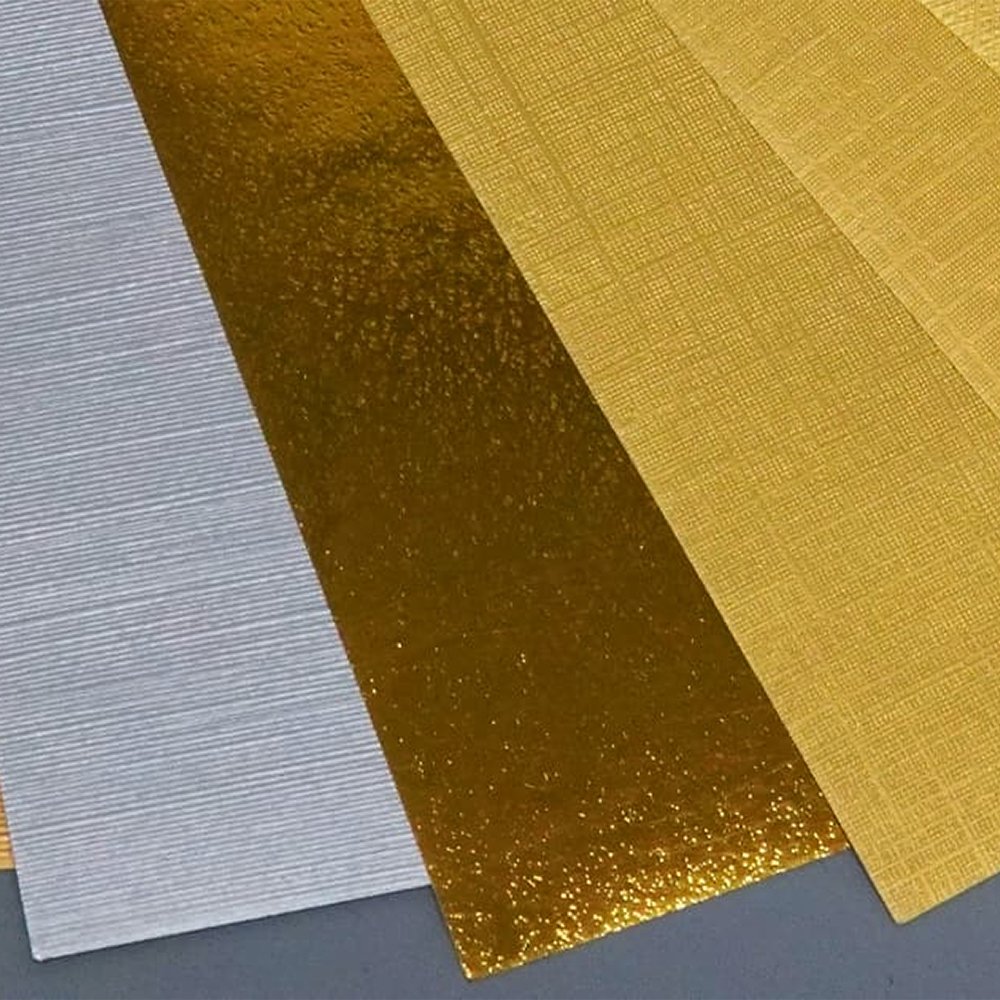

Pantone Metallic Ink

Pantone metallic ink adds a shimmering, reflective finish that instantly upgrades your design. These are available in a range of metallic shades that are great for custom packaging.

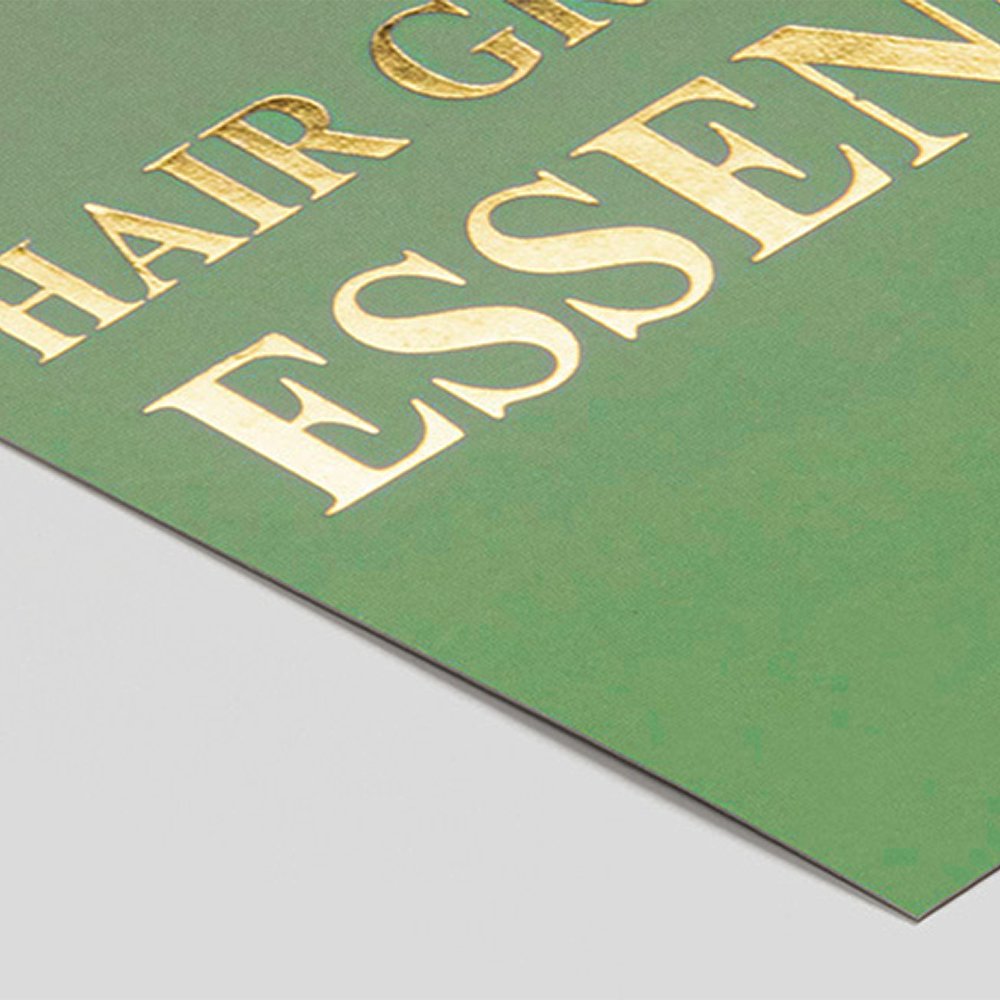

Hot Foil Stamping

Hot foil stamping uses heat and pressure to press metallic foil onto your packaging. It creates a shiny finish, so it’s perfect for logos or accents that need to appear luxurious.

Cold Foil Printing

Cold foil printing applies metallic foil without heat, using UV-curable adhesive. It’s fast and flexible, offering vibrant foil effects in-line during printing. It is a form of relief printing.

Blind Embossing

Blind embossing raises the surface without any ink or foil, creating a clean, textured design. It adds a subtle, elegant dimension. It is a type of relief printing.

Blind Debossing

Blind debossing presses a design into the material without using ink or foil. It gives a recessed effect. And it adds a refined feel to minimalist packaging.

Registered Embossing

Another form of relief printing. Registered embossing combines embossing with print or foil for perfect alignment. It adds texture and depth to printed elements like logos or text.

Combination Embossing

Combination embossing pairs foil stamping with embossing in one step. The result is a rich, multi-dimensional effect that gives your packaging a bold, tactile luxury finish.

Window Patching

Window patching adds a clear plastic window to your packaging, giving customers a sneak peek inside. It’s great for showcasing products to build trust and to establish your brand’s value.

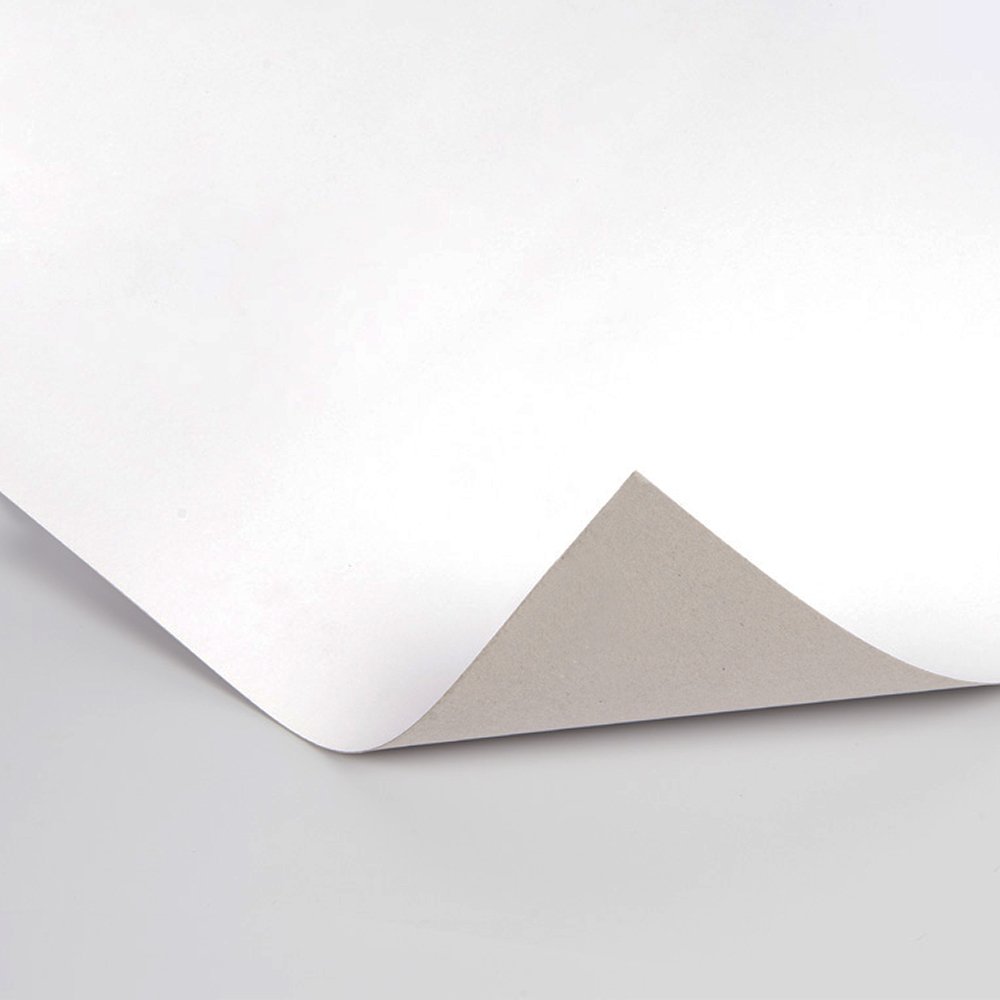

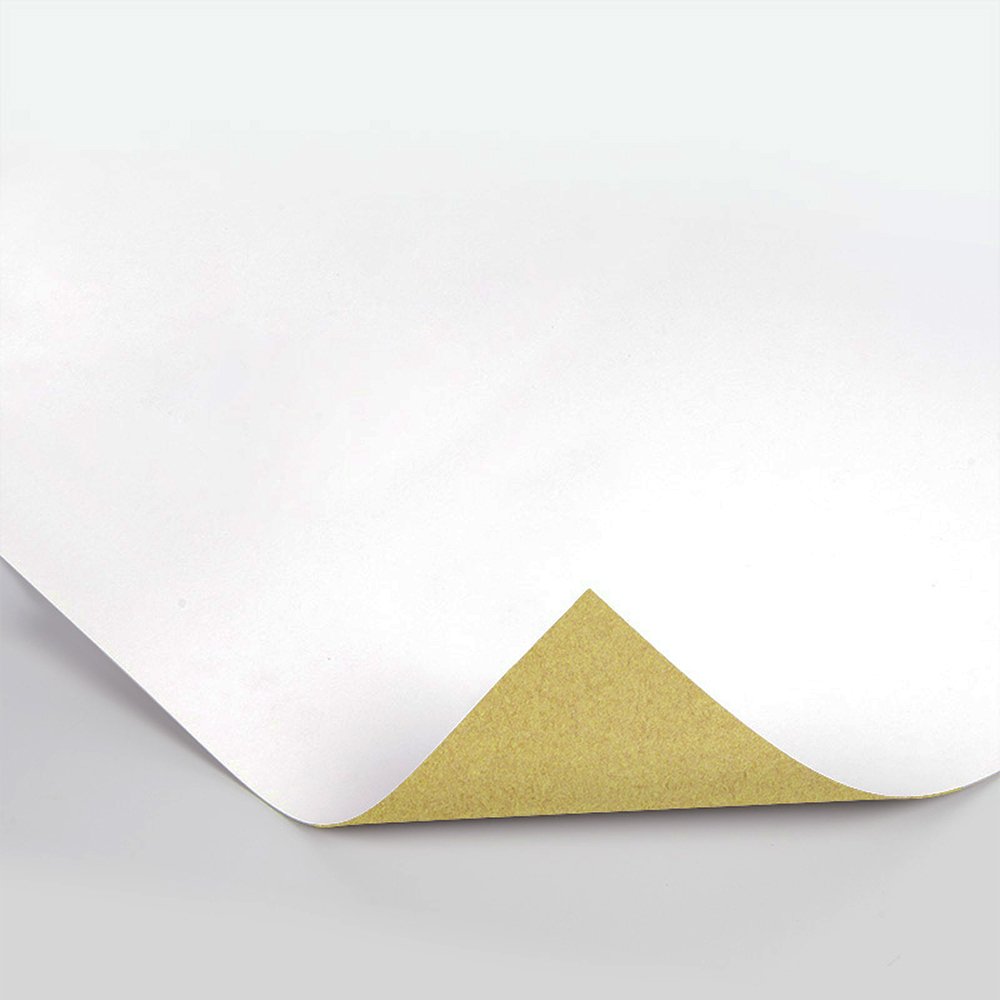

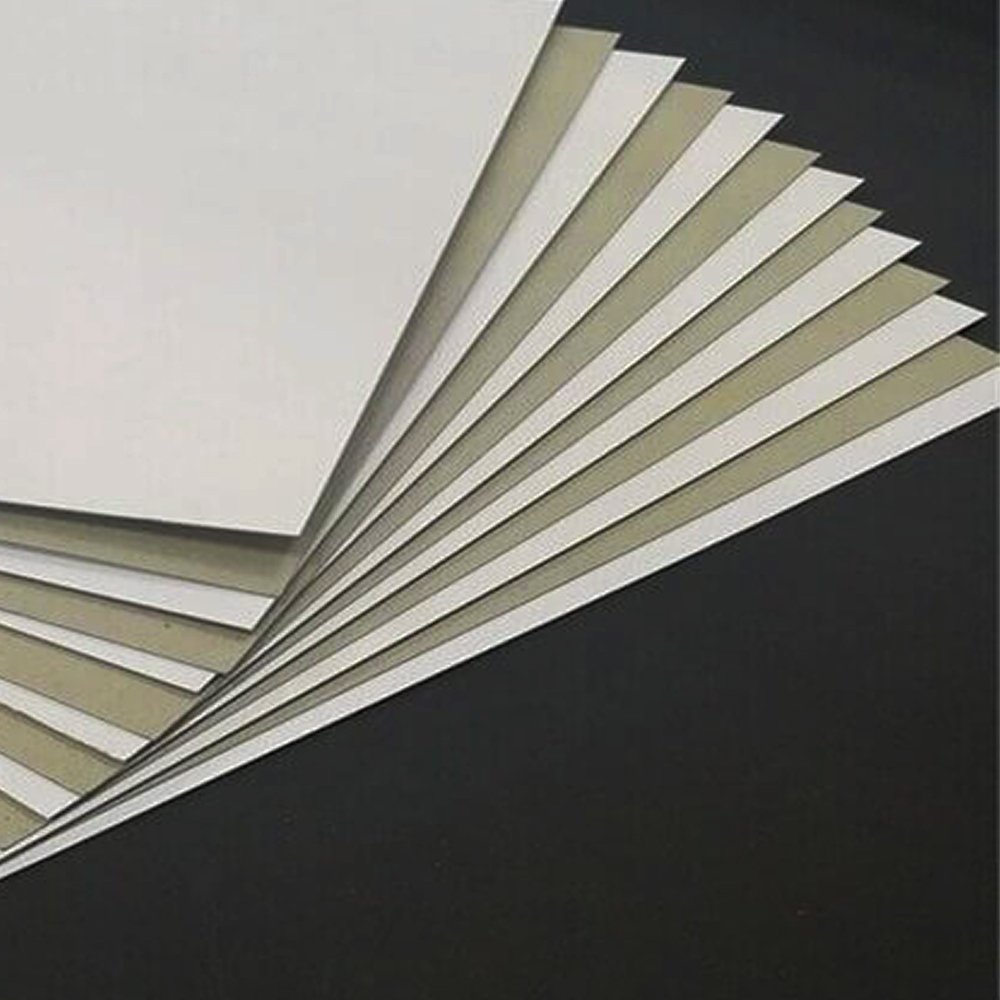

SBS C1S

Solid Bleached Sulfate with Coated One Side (C1S) offers a smooth, printable surface on the front and a natural white back. It gives a sharp print quality with a clean look.

SBS C2S

SBS C2S is coated on both sides, delivering excellent print results inside and out. With its bright white finish and sturdy structure, it’s perfect for premium boxes.

CCNB

Clay Coated News Back (CCNB) is made from recycled material with a white clay-coated front and a dull gray back. It’s cost-effective and best for everyday packaging.

CCNB with FR

CCNB with FR (Food-Grade Resistant) adds a layer of food-safe resistance to standard CCNB. It’s a smart choice for takeout packaging and food products with a protective finish.

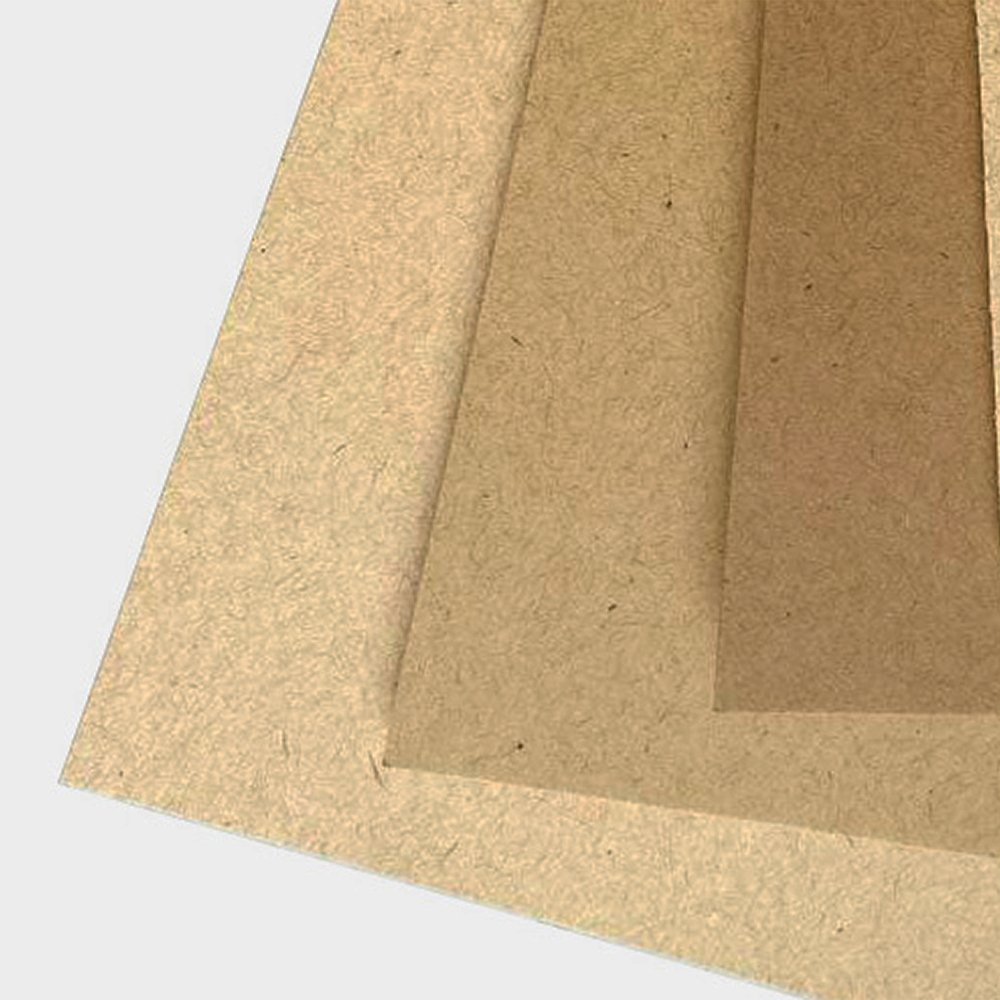

Natural Brown Kraft

Natural brown kraft paperboard has an earthy, organic look with a strong, raw finish. It’s 100% recyclable and gives a natural feel that communicates authenticity and sustainability.

White Kraft

White kraft paperboard has the strength of brown kraft but with a clean, bright white surface. It’s a versatile option for printing, giving a crisp and fresh appearance.

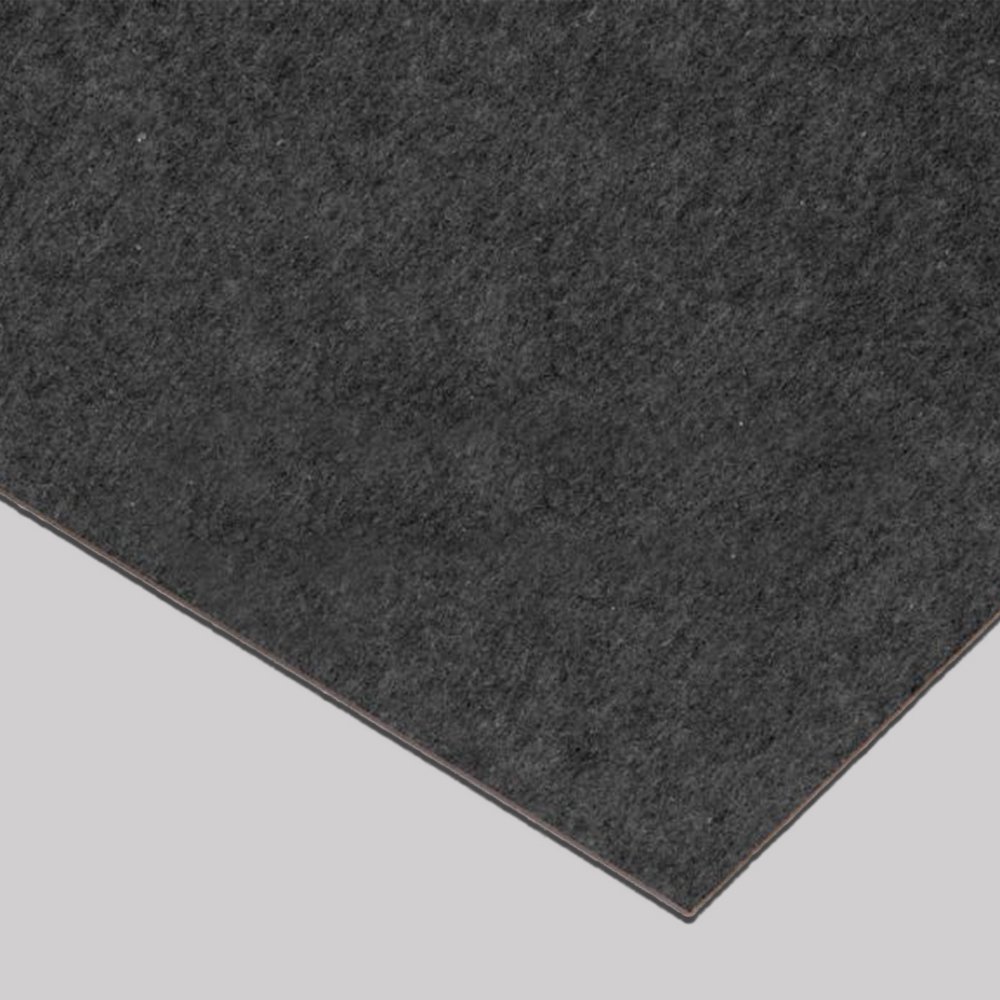

Black Kraft

Black kraft paperboard brings bold, deep tones to your packaging with a sleek, modern vibe. It’s naturally durable and stylish, perfect for luxury products looking for minimal, high-impact presentation.

Uncoated Unbleached Kraft

This kraft board is raw, rustic, unbleached, and uncoated for a completely natural look. It’s ideal for brands that are looking for packaging that is strong, simple, and earthfriendly.

Clay Coated Kraft Back

Clay Coated Kraft Back (CCKB) offers a white, printable front with a kraft brown back. It balances good print quality with a strong and eco-friendly backside.

Clay Natural Kraft

Clay Natural Kraft features a clay-coated printable side with a natural kraft reverse. It combines excellent printability with an organic aesthetic, delivering both performance and earthy character in one eco-smart option.

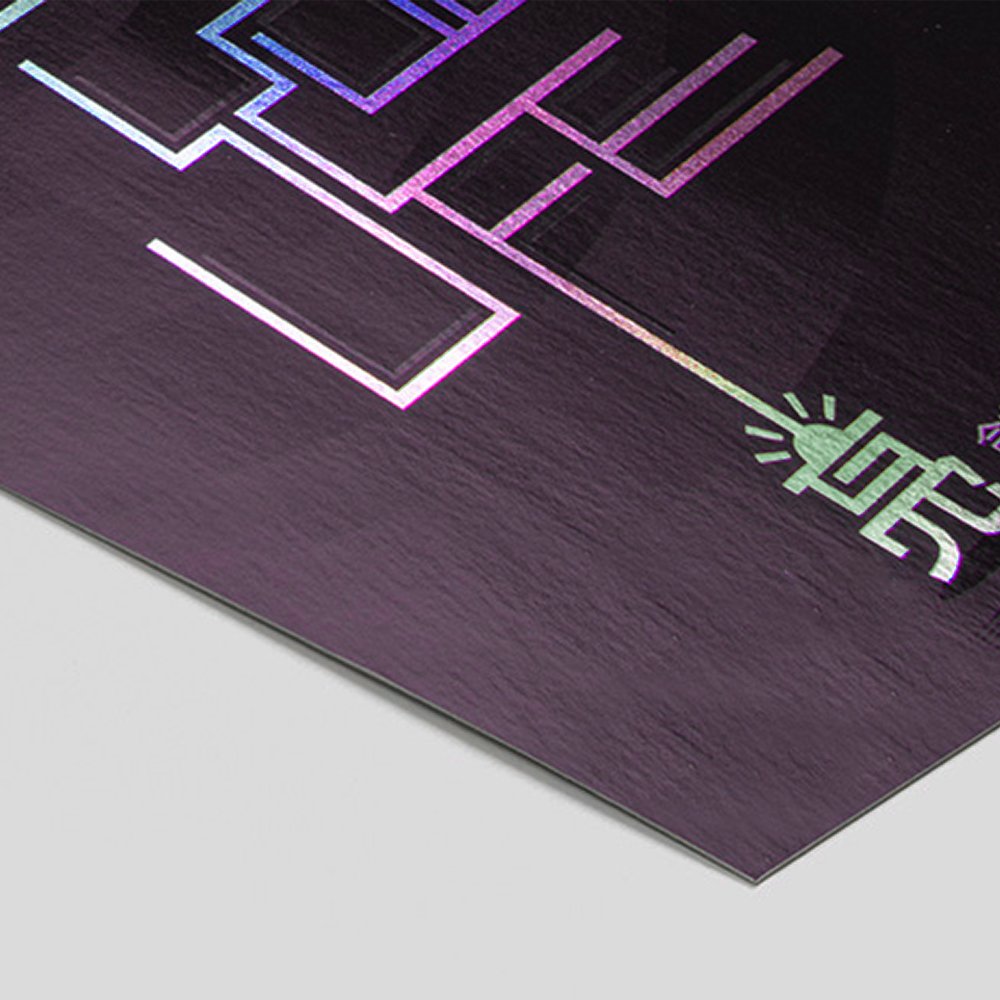

Metallic

Metallic paperboard has a shiny, reflective surface that adds an instant wow factor. Available in gold, silver, and more, it brings bold flair to packaging that demands attention.

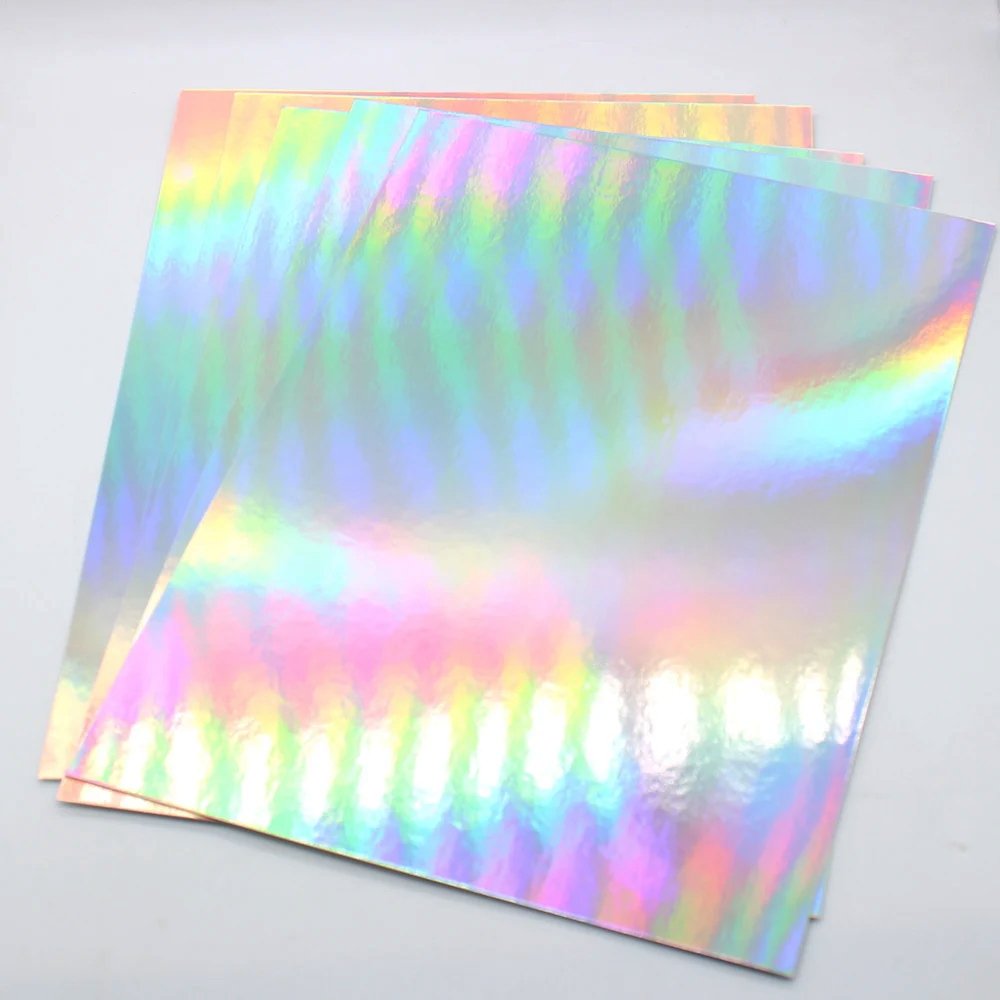

Holographic

Holographic paperboard sparkles with shifting rainbow effects, perfect for futuristic packaging. It changes colors as it moves, making products look vibrant, high-energy, and impossible to ignore.

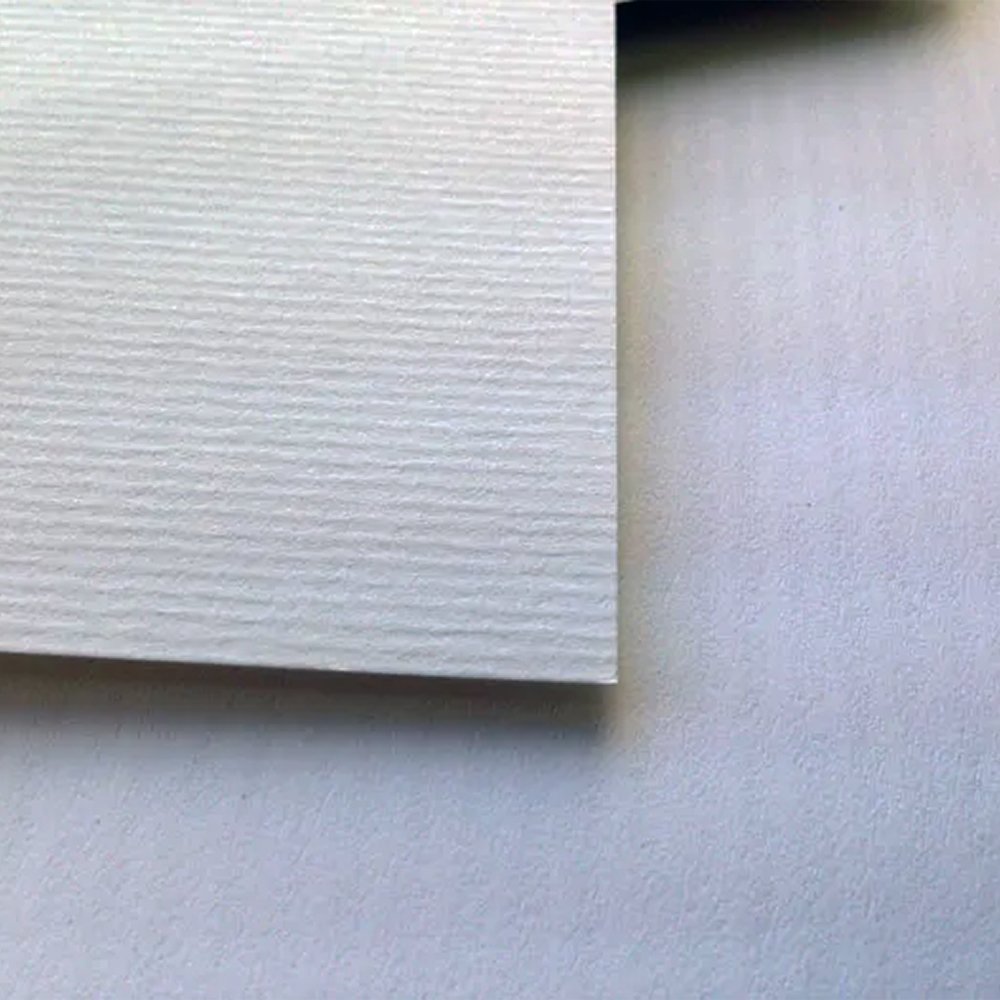

Textured

Textured paperboard adds a tactile dimension with linen, leather, or custom-feel surfaces. It makes packaging more memorable, giving it an upscale, premium character that is different from standard finishes.

Natural Kraft Board

Natural kraft board has a strong, earthy look with its brown, unbleached surface. It’s eco-friendly and durable. These are perfect sustainable packaging with a raw, organic texture.

Oyster White Board

Oyster white board offers a slightly grayish-white tone on one side with a natural back. It’s more refined than brown kraft but still cost-effective. It provides soft-toned finish.

Kemi White Board

Kemi white board has a high-brightness coated surface with a natural kraft back. It’s tear-resistant and prints beautifully, making it a solid pick for high-quality packaging.

Bleached White Board

Bleached white board is fully white inside and out, giving packaging a premium look. It gives the luxury touch to products with light colors that need a pure, crisp canvas.

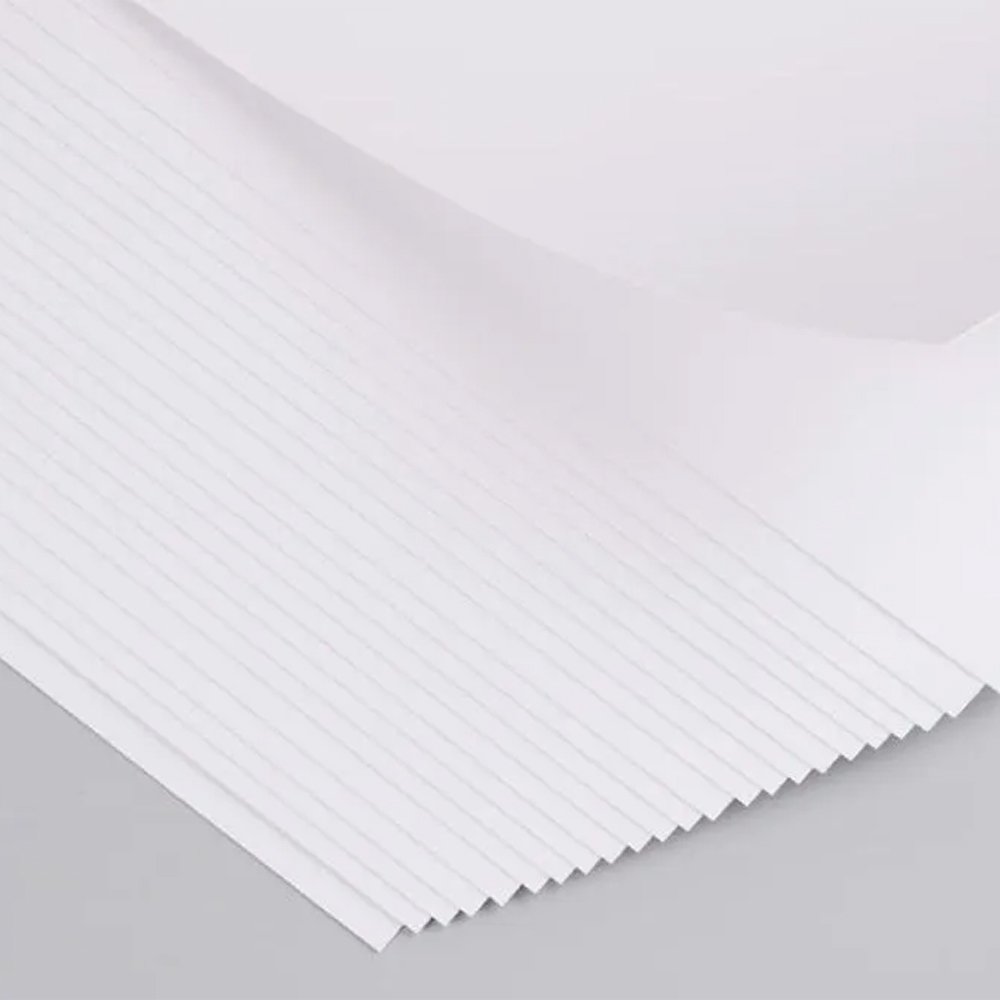

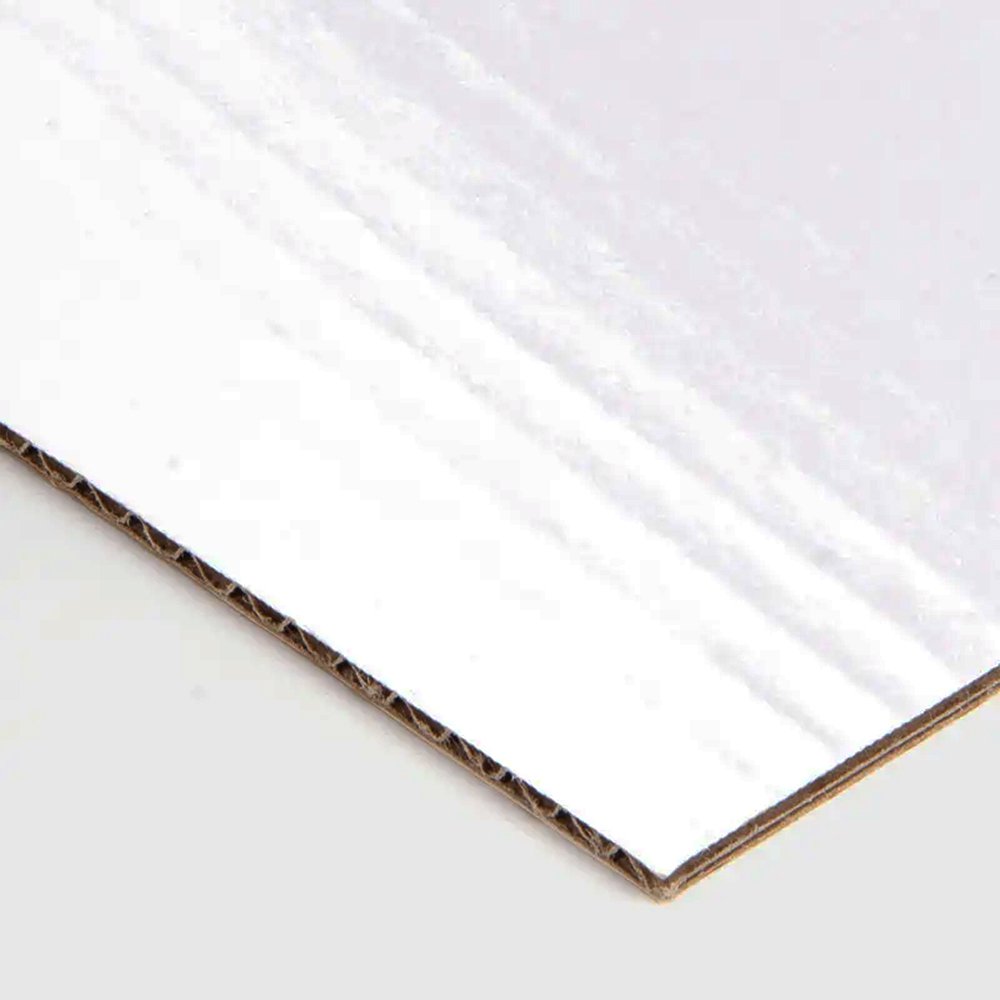

Single Face

Single face board has one flat liner and one fluted layer. It’s flexible and lightweight, great for wrapping or cushioning products that need protection during transportation.

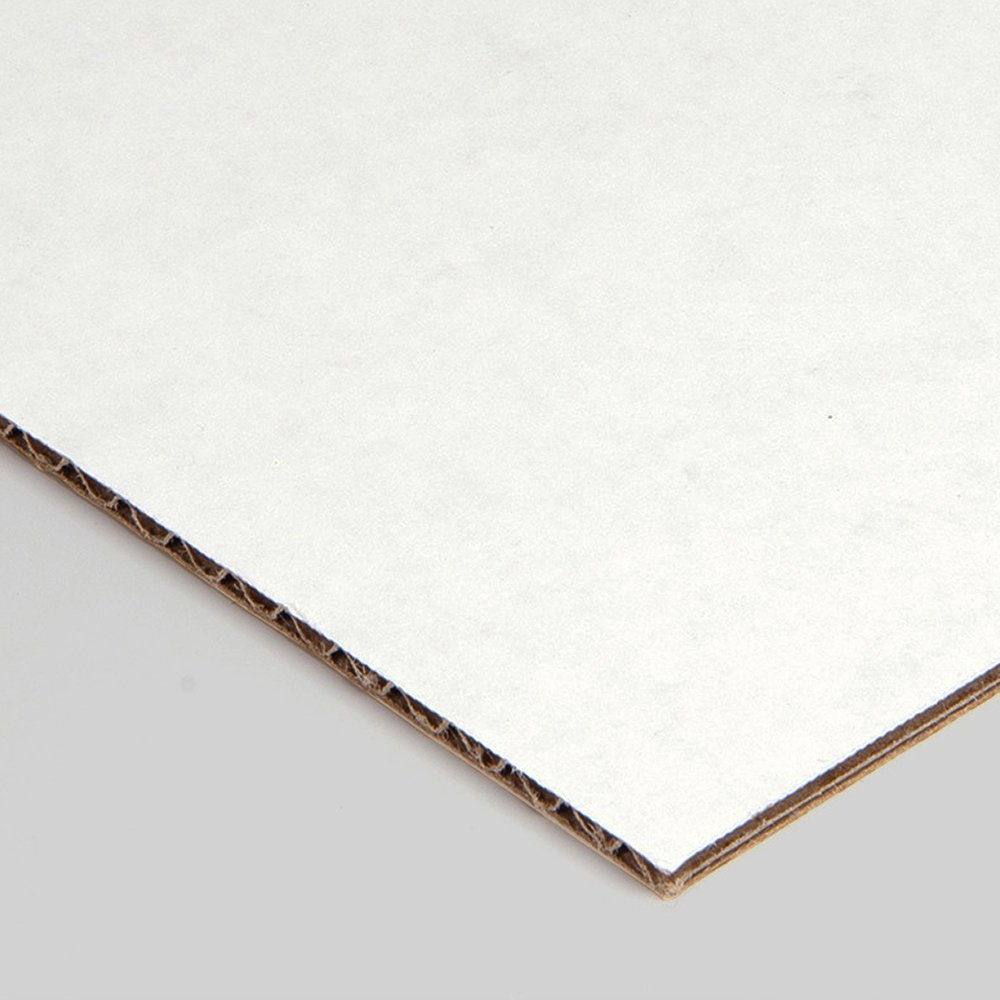

Single Wall

Single wall consists of one layer of fluting between two liners. It’s the most common type for standard boxes, offering good strength and protection for shipping or retail packaging.

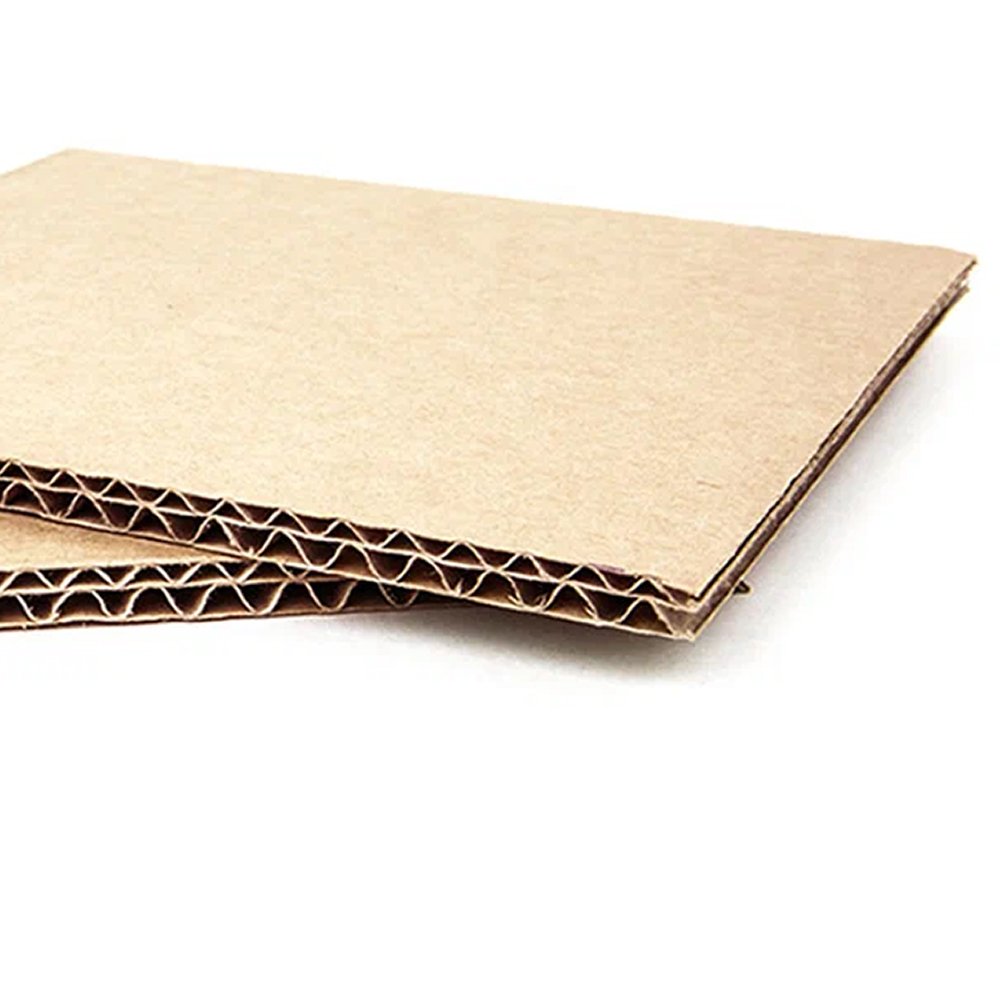

Double Wall

Double wall has two layers of fluting and three liners. It’s tougher and more durable, making it perfect for heavier items that need extra cushioning and stacking strength.

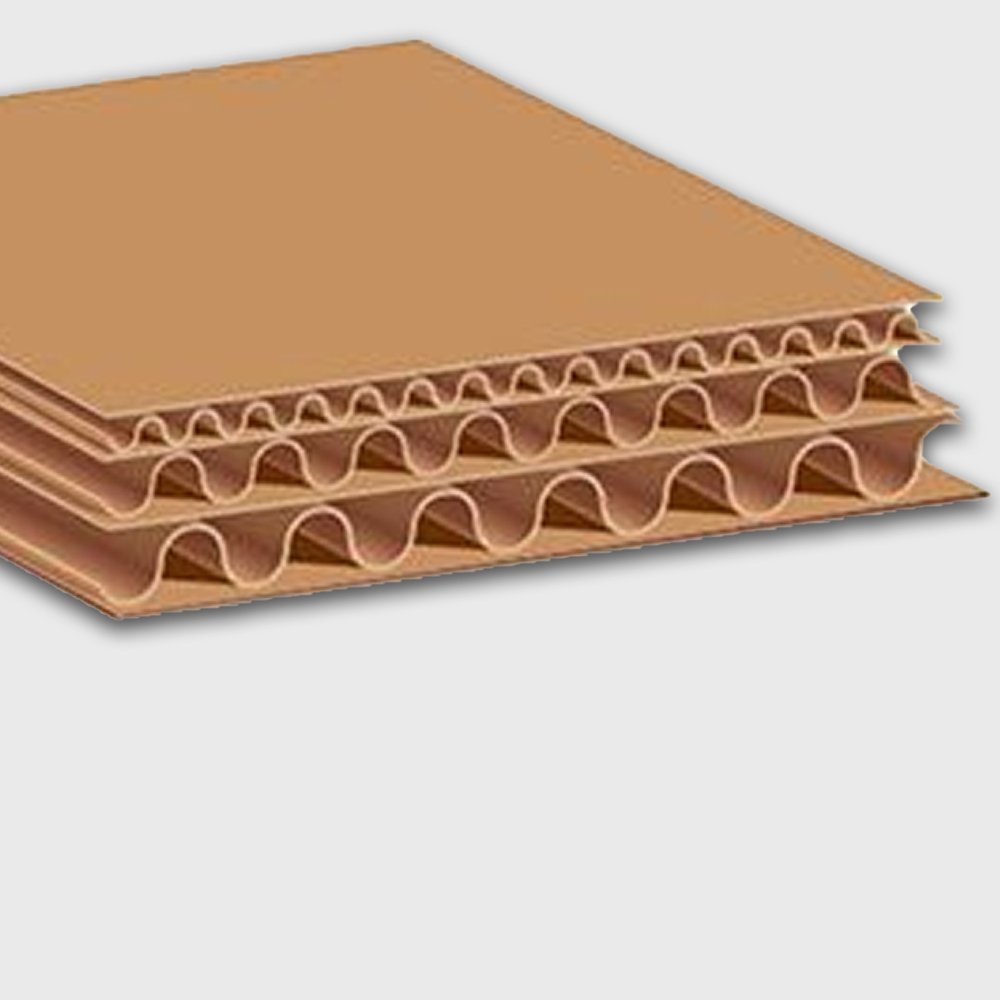

Triple Wall

Triple wall includes three layers of fluting with four liners. They are super strong and built for heavy-duty use. It’s like the tank of corrugated boards to hold products.

A-Flute

A-flute is thick and cushy with great stacking strength. It’s often used for fragile or delicate items where protection matters most because of its excellent shock absorption.

B-Flute

B-flute is thinner and denser, offering a smooth surface that prints well. It’s commonly used for retail packaging, folding cartons, or displays that need strength.

C-Flute

C-flute balances strength and cushioning, making it the most widely used flute for shipping boxes. It handles pressure well and offers good protection for a range of products.

E-Flute

E-flute is slim and sleek, perfect for custom-printed retail boxes. It offers decent strength with a smooth surface for high-quality graphics, ideal for displaying goods without adding bulk.

F-Flute

F-flute is ultra-thin and ideal for small boxes or fine, detailed printing. It gives a premium feel while staying lightweight. These are for specialty packaging and small retails.

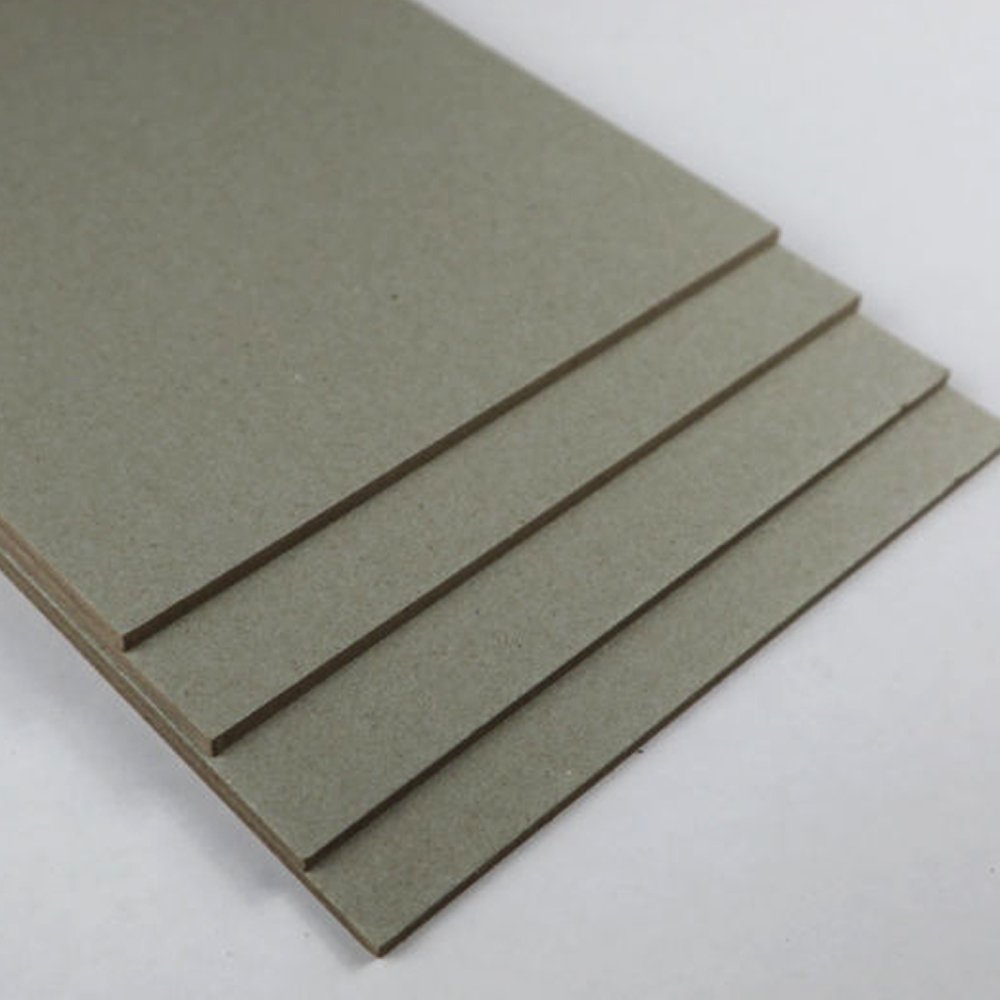

Grey Chipboard

Grey chipboard is a dense, recycled paperboard with a raw, gray finish. It’s perfect for rigid boxes, book covers, or inserts where structure matters more than appearance.

Duplex Chipboard

Duplex chipboard has a grey back and a smooth white front, allowing for better printing while keeping costs low. It is made from recycled paper pulp for printing.

Frequently Asked Questions

You have questions?

Got a question? Take a look at our FAQs about the custom packaging process.

Yes, we have a minimum order requirement, which varies depending on the box type and customization level. Connect to get a quote now.

Design approval to final delivery typically takes 6-8 business days, depending on the complexity and quantity. Reach out to us and get information from us.

Yes, the more you order, the more you save. We offer tiered pricing for large-volume orders. Connect to get more information.

Setup fees may apply for intricate designs or special tooling, but we’ll inform you beforehand. Connect to get more information.

Yes, you can use our online quote form or contact our team for a quick and accurate pricing estimate. Connect to get more information.

USA

USA

UK

UK

CA

CA

.png) Free Shipping

Free Shipping

Design Support

Design Support

Customization

Customization